Civilian Activities

Civilian Activities

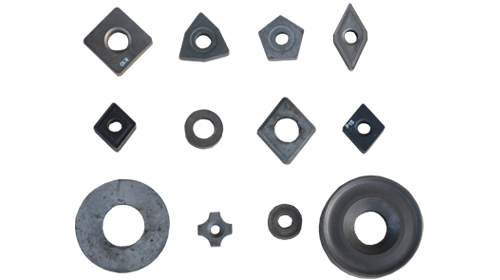

CARBIDE GRADES FOR MILLING

| GRADE |

FIELD OF APPLICATION ACC. TO ISO

|

MACHINING TYPE

|

|

|

Basic

|

Supplementary

|

||

| BS1P | P10 | P01-P15 | Finishing and light roughing of steel castings at high cutting speeds and moderate feeds under favourable working conditions. Withstands very high cutting temperatures. |

| BGC135 | P20K10 | P15-P25K05-K20 | Light roughing of steel, steel castings, malleable cast iron and modular cast iron. Very high wear resistance. Unfavourable conditions. |

| BSM | P25 | P15-P30 | Milling of steel and steel castings, very high resistance to thermal shocks and shocks and plastic deformation. Very good toughness. |

| BSM30 | P30 | P20-P40 | Milling of steel, steel castings in operations where there are simultaneous demands for toughness, wear resistance and resistance to thermal cracking. |

| BS6 | P40 | P30-P45 | Roughing of carbon steel, stainless steel and steel castings at low cutting speeds, difficult working conditions. Used for large cutting depths and heavy feeds. |

| BH20 | M20K20 | Finishing and light roughing of wide variety of high alloy steel materials, heat resistant alloys. Low cutting speeds and high feeds. |

|

| BH1P | K10 | K05-K15 | Finishing and roughing of cast iron, bronze and brass. High cutting speeds and moderate feeds. |

| BHM | K15 | K10-K20 | Developed especially for milling low-alloy cast iron, E.G. castings for the automotive industry. Very high resistancr to wear and plastic deformation. |

| BGC315 | K15 | K10-K20 | Light roughing of cast iron and other shortchipping materials. Very high wear resistance. |